Silicon carbide is becoming an important player in the quantum scene. Widely used in specialized electronic devices like LED diodes and electric vehicles, silicon carbide allows for broad commercial applications and increasing utilization in high-power electronics, making it an attractive material for quantum information science with profound impact.

By utilizing physics at the atomic level, technologies such as quantum computers, networks, and sensors are likely to revolutionize diverse fields such as communication, drug development, and logistics in the coming decades.

Now, scientists from the U.S. Department of Energy’s Argonne National Laboratory, Sandia National Laboratories, and partner institutions have conducted comprehensive research on creating qubits – the fundamental units of quantum information processing – in silicon carbide.

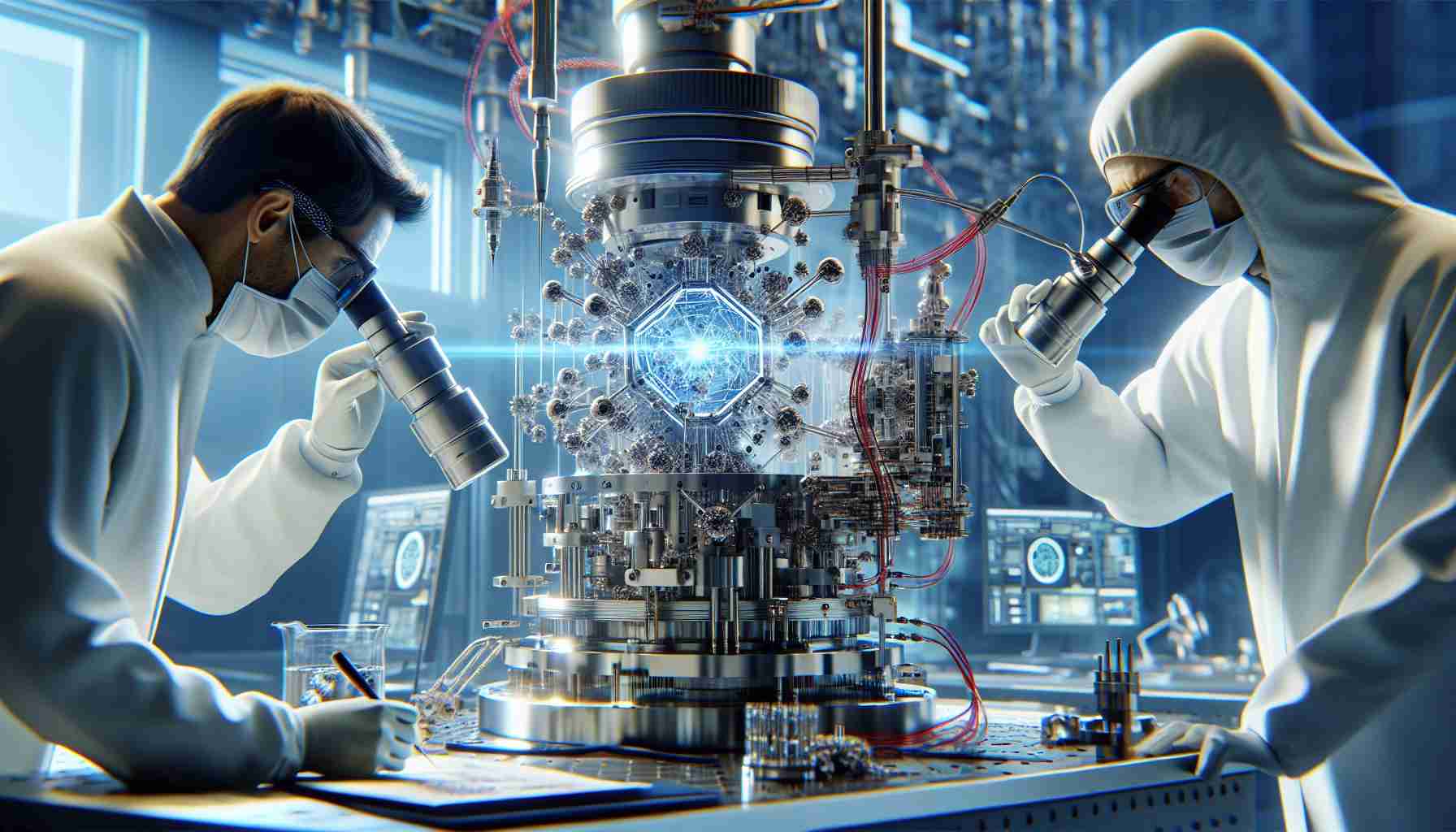

In a groundbreaking study, researchers from Argonne and Sandia used state-of-the-art nanoscale research tools in two laboratories and successfully demonstrated the method of creating qubits in silicon carbide with exceptional precision. They also conducted high-level analyses, such as atomic-level silicon carbide’s response to qubit implantation.

Their findings enable scientists to better design quantum circuits for specific purposes, whether it’s designing ultra-precise sensors or building secure communication networks.

The scientists’ work has been published in the Nanotechnology journal.

“We can better understand the molecular dynamics of the material beyond the typical, general explanation that we know,” said the article’s author, Argonne’s Delegate. “We also showed that we can create qubits with spatial localization in this very important material, which is silicon carbide.”

The researchers are working on refining the process of creating qubits in silicon carbide. These qubits take the form of two neighboring atomic-sized defects inside the silicon carbide crystal. Scientists refer to this pair of atomic defects as a divacancy.

The research team developed a method to create qubits by utilizing a process perfected at the Sandia Integrated Nanotechnologies Center (CINT). Using one of CINT’s nanomaterial tools, scientists were able to precisely implant silicon ions into silicon carbide. This process causes the release of silicon carbide atoms, creating a divacancy in the material.

This process allows scientists not only to determine the exact number of atoms to introduce into the silicon carbide, but also to place the divacancy with a precision of about 25 nanometers. Such precision is crucial for integrating quantum technologies into electronic devices.

After the precise placement of qubits, the Argonne scientists subjected the silicon carbide samples to a hardening process to improve the properties and stabilize the silicon carbide crystal.

They then mapped, for the first time, the formation of divacancies inside the crystal and changes in its nanoscale structure after the hardening process. Their tool for this characterization was the powerful Advanced Photon Source (APS) at Argonne, a U.S. Department of Energy scientific facility.

APS is a massive ring-shaped machine, large enough to encircle a sports stadium. It produces highly intense X-ray beams to peer deep into materials.

Scientists from Argonne’s Center for Nanoscale Materials (CNM), also a U.S. Department of Energy scientific facility, used the dedicated CNM X-ray beamline in the APS to investigate the mobilization and formation of divacancy qubits inside silicon carbide. How many defects are formed when you adjust the number of implanted atoms? What happens when you adjust the energy of the atom? How does implantation affect the structure of silicon carbide?

“These impurities lead to different crystalline configurations that cause strains,” said Titze. “How is the strain influenced by these different defects?”

To answer these questions, the team focused a thin 25-nanometer X-ray beam on the silicon carbide samples.

“You can scan the entire volume of material and always get information about the structure of what’s happening,” said Delegate. “Now you have a way to look at those scales using X-rays. You can say, ‘How was the crystal behaving before implantation, during, and after?'”

Using the CNM X-ray beamline at the APS, the team was able to visualize the changes in the nanoscale structure of silicon carbide with impressive high-resolution, detecting changes at a level of 1 in a million.

By combining the precise placement of qubits using the CINT tool and the precise imaging of their crystalline environment using Argonne’s APS and CNM, the team takes a significant step towards creating tailored silicon carbide qubits, leading to greater possibilities for customization in quantum applications.

Their work also provides new insights into silicon carbide qubits, enabling the scientific community to develop and fine-tune their silicon carbide-based quantum devices in a purposeful manner.

“This work enables all of these quantum information science applications in which you want to implant a very specific ion because of its useful quantum properties,” said Titze. “You can now use this knowledge of local strain around defects to design it in a way that you can make hundreds of defects on one chip talk to each other.”

The team’s collaboration stands as a testimony to interinstitutional cooperation.