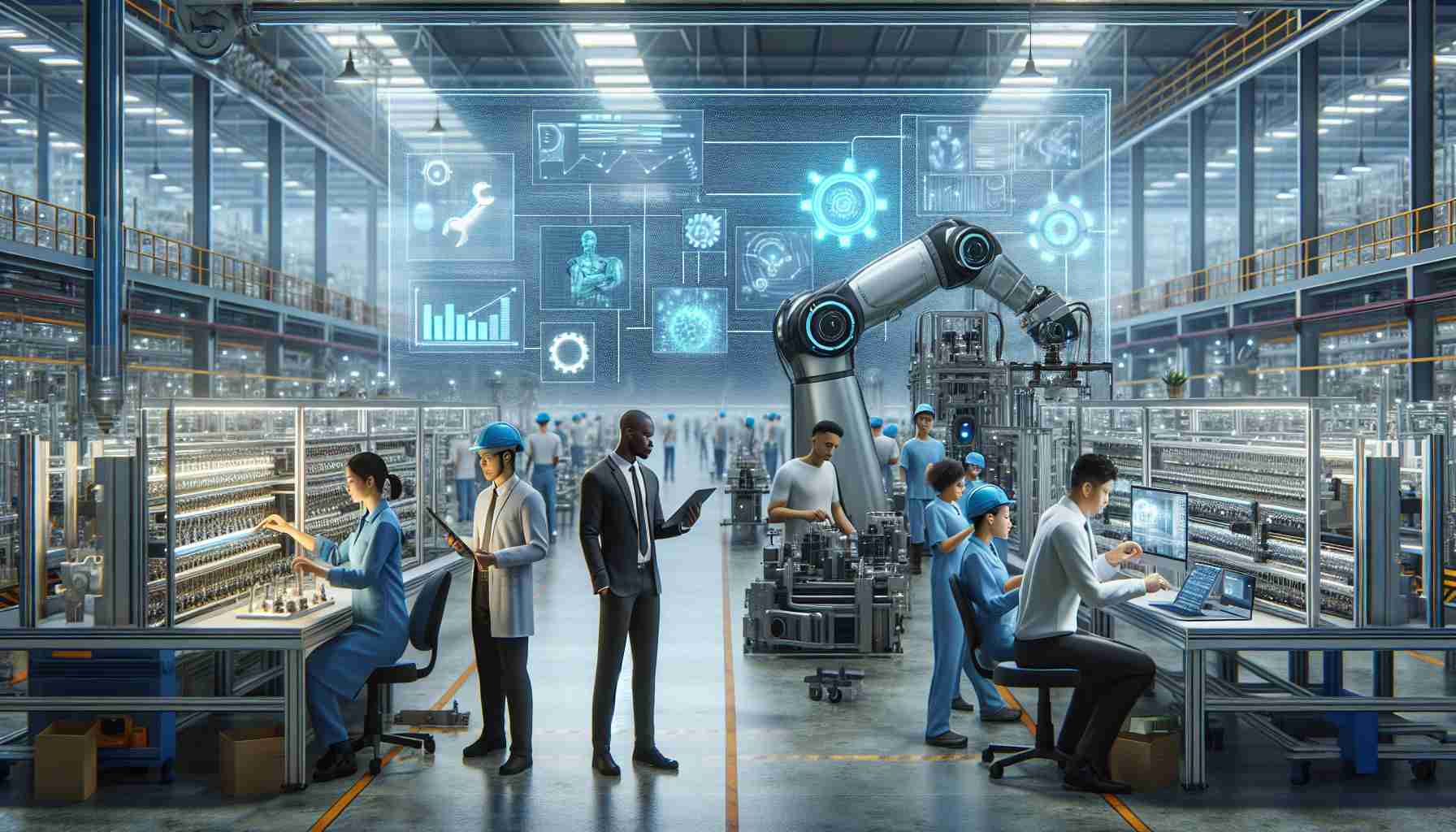

Revolutionizing the Manufacturing Sector with High-Tech and AI Innovations

In the aftermath of the global pandemic, the manufacturing industry is witnessing a significant transformation influenced by technological advancements and innovation. The focus has shifted towards leveraging high-level technology to enhance production capabilities and drive economic growth.

Shift towards New Quality Production

The current economic landscape demands a shift towards developing new quality production methods to propel high-quality development. This transition includes revamping and upgrading traditional industries while fostering the growth of high-tech and emerging sectors. The emphasis is on nurturing innovation and integrating digital technologies to create a more efficient and sustainable manufacturing ecosystem.

China’s Dominance in Manufacturing

China’s robust manufacturing industry stands out as a key player in the global market post-pandemic. With an emphasis on self-sufficiency in high-level technology, China’s manufacturing sector is poised to lead the development of new quality production forces. This strategic direction not only benefits the domestic market but also presents lucrative investment opportunities for international investors.

Investment Opportunities in High-End Manufacturing

Specifically, focusing on sectors such as high-end manufacturing and AI-driven technologies presents promising investment opportunities. The demand for high-end products remains strong in emerging markets, complemented by China’s evolving economic landscape. Industries such as automotive components and specialized equipment are witnessing a surge in demand, signaling potential growth and resilience amidst global uncertainties.

Harnessing AI Innovations for Manufacturing

The widespread integration of AI technologies across various industries is driving innovation and reshaping the manufacturing landscape. AI-powered technologies are revitalizing the consumer electronics market and propelling semiconductor industry growth. Moreover, the increasing demand for computing power is set to benefit infrastructure development, particularly in the realm of digitalization and AI applications.

In conclusion, the post-pandemic era presents a unique opportunity for the manufacturing sector to embrace technological advancements and redefine production methodologies. By focusing on high-tech innovations and quality production processes, the manufacturing industry can adapt to changing market demands and drive sustainable growth in the long term.

Transforming Manufacturing Industry Post-Pandemic: Embracing Innovation and Overcoming Challenges

As the manufacturing industry undergoes a profound transformation post-pandemic, several key questions arise regarding the future trajectory of this sector. How can companies effectively harness high-tech innovations to enhance their production capabilities and remain competitive in the global market? What are the primary challenges associated with adopting new quality production methods, and how can these obstacles be overcome to drive sustained growth? Let’s delve into these critical aspects and explore the advantages and disadvantages of the evolving manufacturing landscape.

Key Questions and Answers:

1. How can manufacturers leverage high-tech innovations effectively? Manufacturers can leverage high-tech innovations by investing in advanced technologies such as Internet of Things (IoT), robotics, and machine learning to automate processes, improve efficiency, and reduce operational costs. Additionally, implementing digital twin technology can enable manufacturers to simulate and optimize production processes in a virtual environment before actual implementation.

2. What are the primary challenges associated with transitioning to new quality production methods? One of the main challenges is the initial investment required to adopt new technologies and retrain the workforce to operate them effectively. Resistance to change and the need for cybersecurity measures to protect sensitive data in a digitized environment are also significant challenges that manufacturers may face during the transformation process.

Advantages:

– Enhanced Efficiency: Adoption of high-tech innovations can streamline production processes, reduce lead times, and improve overall efficiency.

– Competitive Edge: Companies embracing new quality production methods can differentiate themselves in the market, attract investment, and meet evolving customer demands.

– Sustainable Growth: By integrating digital technologies and fostering innovation, manufacturers can establish a sustainable ecosystem that drives long-term growth and resilience.

Disadvantages:

– Costly Implementation: The upfront costs associated with integrating high-tech innovations can be substantial, requiring careful financial planning and resource allocation.

– Workforce Disruption: Transitioning to new production methods may disrupt traditional roles within the workforce, necessitating retraining and upskilling initiatives.

– Cybersecurity Risks: Increased digitization exposes manufacturers to cybersecurity threats, highlighting the importance of robust data protection measures and risk management strategies.

As the manufacturing industry navigates the complexities of post-pandemic recovery and transformation, addressing these challenges while capitalizing on the opportunities presented by technological advancements will be paramount to sustained success. By embracing innovation, nurturing talent, and adapting to changing market dynamics, manufacturers can position themselves at the forefront of a new era of industrial revolution.

For further insights into the latest trends and developments in the manufacturing sector, visit Manufacturing Tech News.