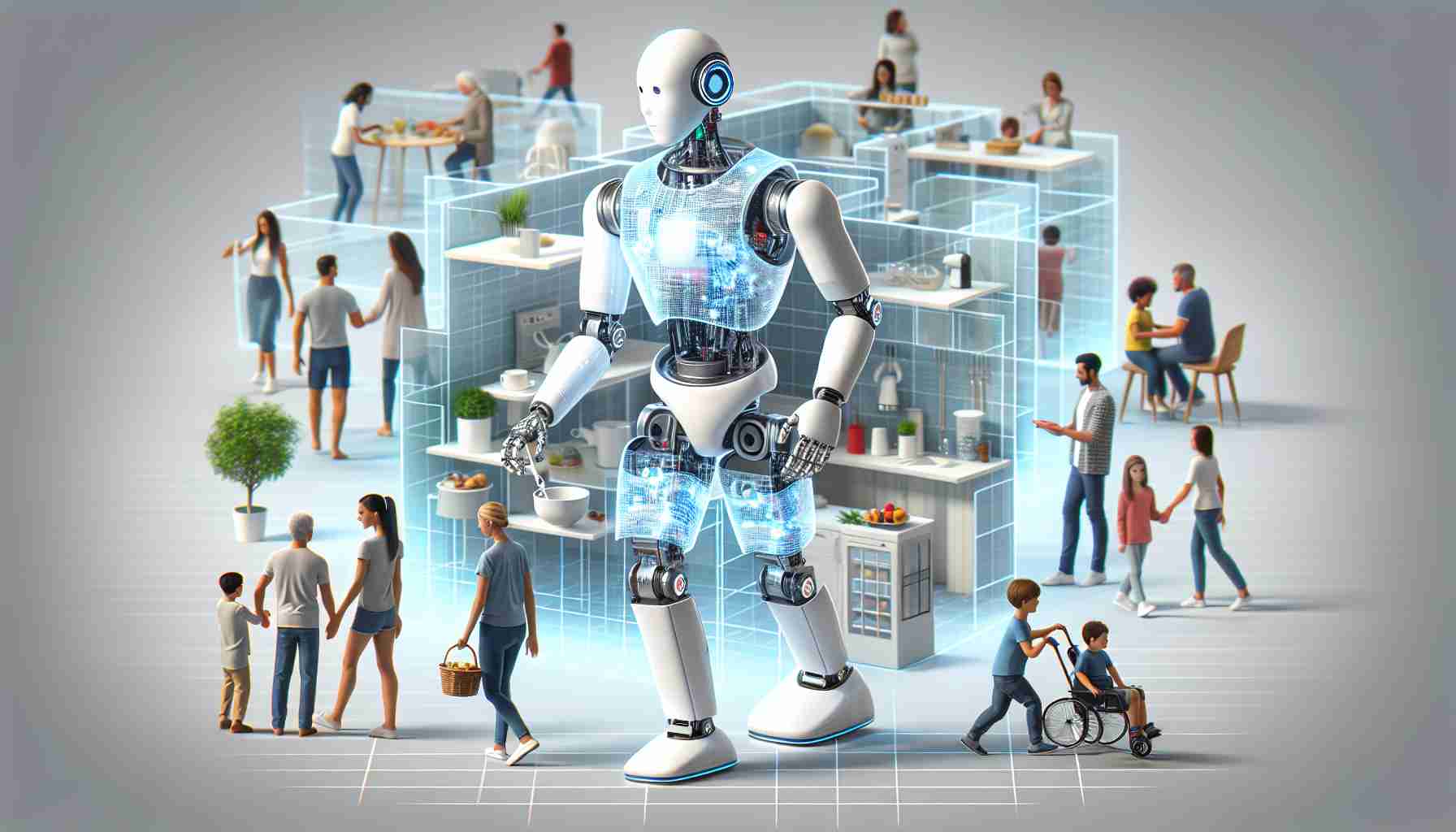

Nio has taken significant strides towards incorporating humanoid robots into its manufacturing processes and beyond. Unlike other car manufacturers, Nio initiated testing humanoid robots in its factories ahead of the curve. The newest addition to their robotic workforce, Walker S from UBTech Robotics, showcased its capabilities in Nio’s factory earlier this year.

During its training, Walker S demonstrated its prowess in quality control tasks, utilizing image capture and transmission features for inspections, including checking door locks and attaching vehicle logos. This marked a groundbreaking moment for NEV factories, presenting a glimpse into the future of automated manufacturing.

Looking towards the future, Nio aims to further enhance its humanoid robots’ capabilities. The company’s focus lies in developing robots that can excel in confined spaces, leveraging 5G technologies and advanced vision algorithms for multitasking assignments. Additionally, the introduction of humanoid robots into quality control tasks is poised to revolutionize production processes, ensuring top-notch product quality. With these advancements, Nio is at the forefront of innovation in the realm of robotics integration.

Nio’s Advancements in Humanoid Robot Integration: Exploring Uncharted Territory

As Nio continues to make strides in integrating humanoid robots into its manufacturing processes, the automotive industry is witnessing a transformative shift towards automation and advanced robotics. Beyond the initial testing phase, Nio is now delving deeper into enhancing the capabilities of its robotic workforce to streamline production and improve efficiency.

What are the key challenges associated with implementing humanoid robots in manufacturing?

One of the primary challenges faced in integrating humanoid robots into manufacturing processes is ensuring seamless collaboration between robots and human workers. Balancing tasks that require precision and dexterity with human-like movements can be complex, requiring extensive programming and coordination efforts. Additionally, maintaining safety standards and preventing accidents in fast-paced manufacturing environments are crucial considerations.

How do Nio’s advancements in humanoid robot integration address these challenges?

Nio’s focus on developing robots tailored for confined spaces and equipped with advanced vision algorithms aims to alleviate some of the challenges associated with traditional industrial robots. By leveraging cutting-edge technologies such as 5G connectivity and sophisticated image processing capabilities, Nio’s humanoid robots are able to navigate complex tasks more efficiently and with enhanced accuracy.

Advantages and Disadvantages of Humanoid Robot Integration in Manufacturing:

Advantages:

– Increased productivity: Humanoid robots can perform repetitive tasks with precision and consistency, contributing to higher output rates.

– Enhanced quality control: Robots equipped with advanced sensors and imaging capabilities can detect defects and ensure product quality standards are met.

– Improved safety: By taking on hazardous or strenuous tasks, humanoid robots help reduce the risk of workplace injuries for human workers.

– Innovation and competitiveness: Embracing robotics integration positions companies like Nio at the forefront of technological advancement and market competitiveness.

Disadvantages:

– Initial investment costs: Implementing humanoid robots requires significant upfront investment in equipment, software, and training.

– Technical complexities: Programming and integrating humanoid robots into existing manufacturing processes can be intricate and time-consuming.

– Workforce concerns: The introduction of robots may lead to job displacement or require reskilling for human workers to adapt to new roles within the production environment.

In conclusion, Nio’s ongoing advancements in humanoid robot integration represent a significant leap towards the future of automated manufacturing. By tackling key challenges and harnessing the potential of innovative technologies, Nio is paving the way for enhanced efficiency, quality, and competitiveness in the automotive industry.

For more information on Nio’s groundbreaking initiatives in robotics integration, visit Nio’s Official Website.