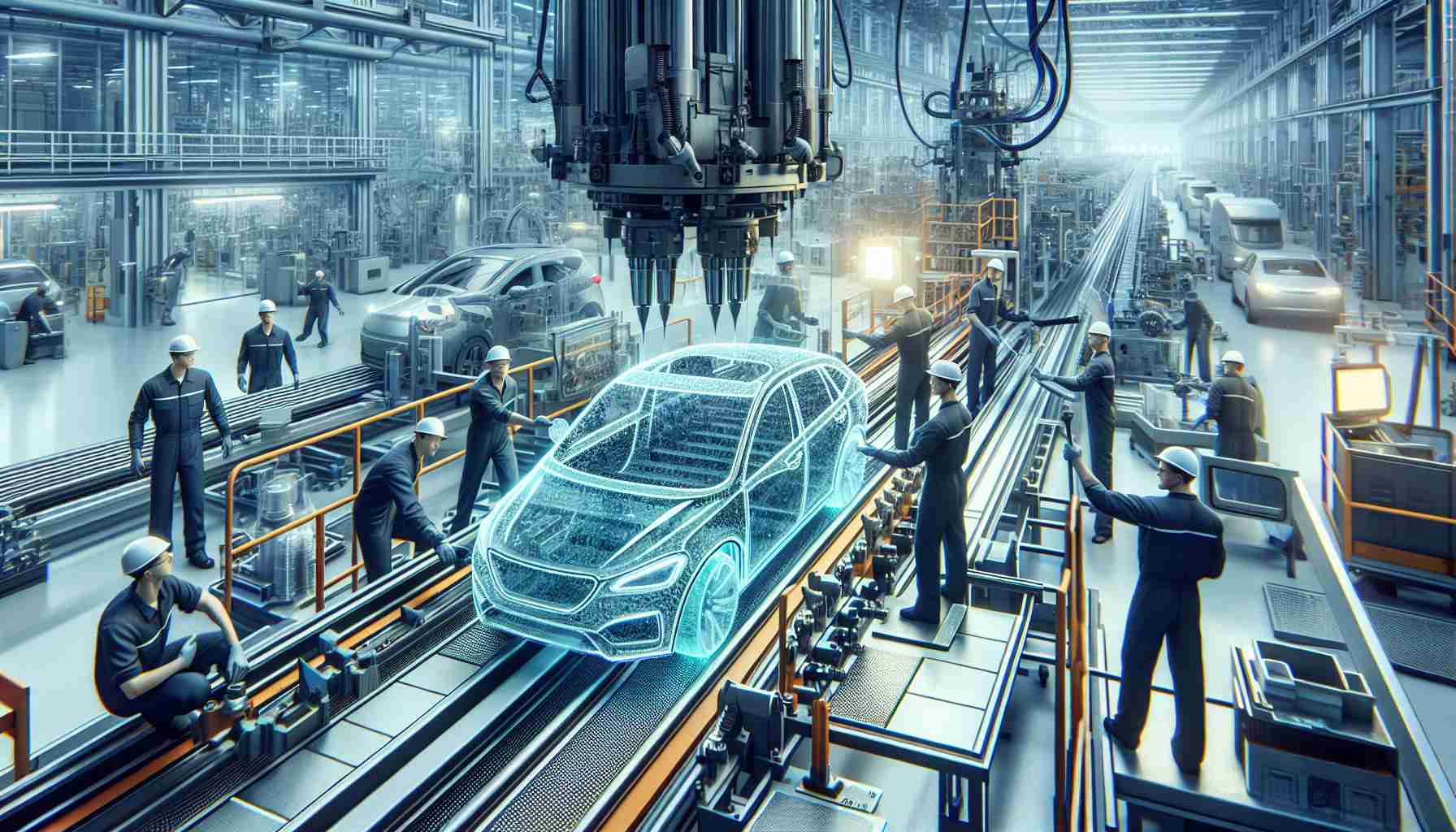

A cutting-edge innovation in automotive glass manufacturing has recently been unveiled by a leading glass company, transforming the way vehicles are equipped. Previous methods of glass production have given way to a groundbreaking technique that not only enhances durability but also raises concerns regarding its potential impact on electronic devices such as smartphones.

Unlike traditional glass manufacturing processes, this new method involves a sophisticated silver coating that has sparked discussions about its effects on signal reception. However, experts assure that this innovative approach incorporates a solution that addresses such concerns head-on. Through a meticulous laser treatment post-coating, specific areas of the glass are cleared to ensure seamless reception of essential signals like ETC and GPS. This customized process guarantees unhindered electronic signal recognition, safeguarding the efficiency of signal transmission without any disruptions.

Disclaimer: This transformative development promises a new era in automotive glass manufacturing and underscores the importance of forward-thinking solutions in the industry. As the automotive landscape continues to evolve, advancements like this are testament to the commitment of companies to prioritize both quality and functionality in their products.

Revolutionizing Automotive Glass Production: Unveiling New Frontiers

A cutting-edge revolution in the realm of automotive glass production has set the stage for a transformative era, propelling the industry towards new heights of innovation and efficiency. With the emergence of a pioneering technique by a leading glass company, the traditional norms of glass manufacturing have been reshaped, offering a glimpse into a future where durability and technology coexist seamlessly.

Unlike its predecessors, this avant-garde method incorporates a sophisticated silver coating that not only bolsters the glass’s resilience but also raises intriguing questions about its impact on electronic devices. The integration of this silver coating has triggered discussions within the industry, particularly concerning signal reception and potential interference with electronic gadgets like smartphones.

Key Questions:

1. How does the new silver coating affect signal reception in automotive glass?

2. What measures are in place to mitigate any signal disruption caused by the silver coating?

3. What advantages does the laser treatment post-coating offer in ensuring uninterrupted signal transmission?

Answers and Insights:

– The silver coating, while enhancing durability, poses challenges related to signal reception due to its reflective nature.

– To counter this, a meticulous laser treatment process is employed post-coating to clear specific areas on the glass, ensuring seamless signal transmission for vital functions like ETC and GPS.

– This tailored approach guarantees optimal signal recognition without compromising efficiency, addressing concerns about possible signal interference effectively.

Advantages and Disadvantages:

– Advantages: Enhanced durability, improved signal transmission, forward-thinking technology integration.

– Disadvantages: Potential signal disruption, initial concerns regarding compatibility with electronic devices.

As the automotive glass production landscape witnesses this profound shift towards innovation, the path forward is marked by a blend of technological prowess and consumer-centric solutions. While the transformative potential of this new approach is undeniable, navigating challenges such as signal interference and technology harmonization remains critical to realizing its full benefits.

Suggested Related Links:

– GlassProduction.com: Explore more insights into cutting-edge developments in glass manufacturing.

– AutomotiveGlass.com: Delve deeper into the world of automotive glass technologies and advancements.