The innovative CleanTech Solutions group has been selected by the renowned Sustainable Manufacturing Institute to spearhead a groundbreaking project focusing on next-generation cleanroom development.

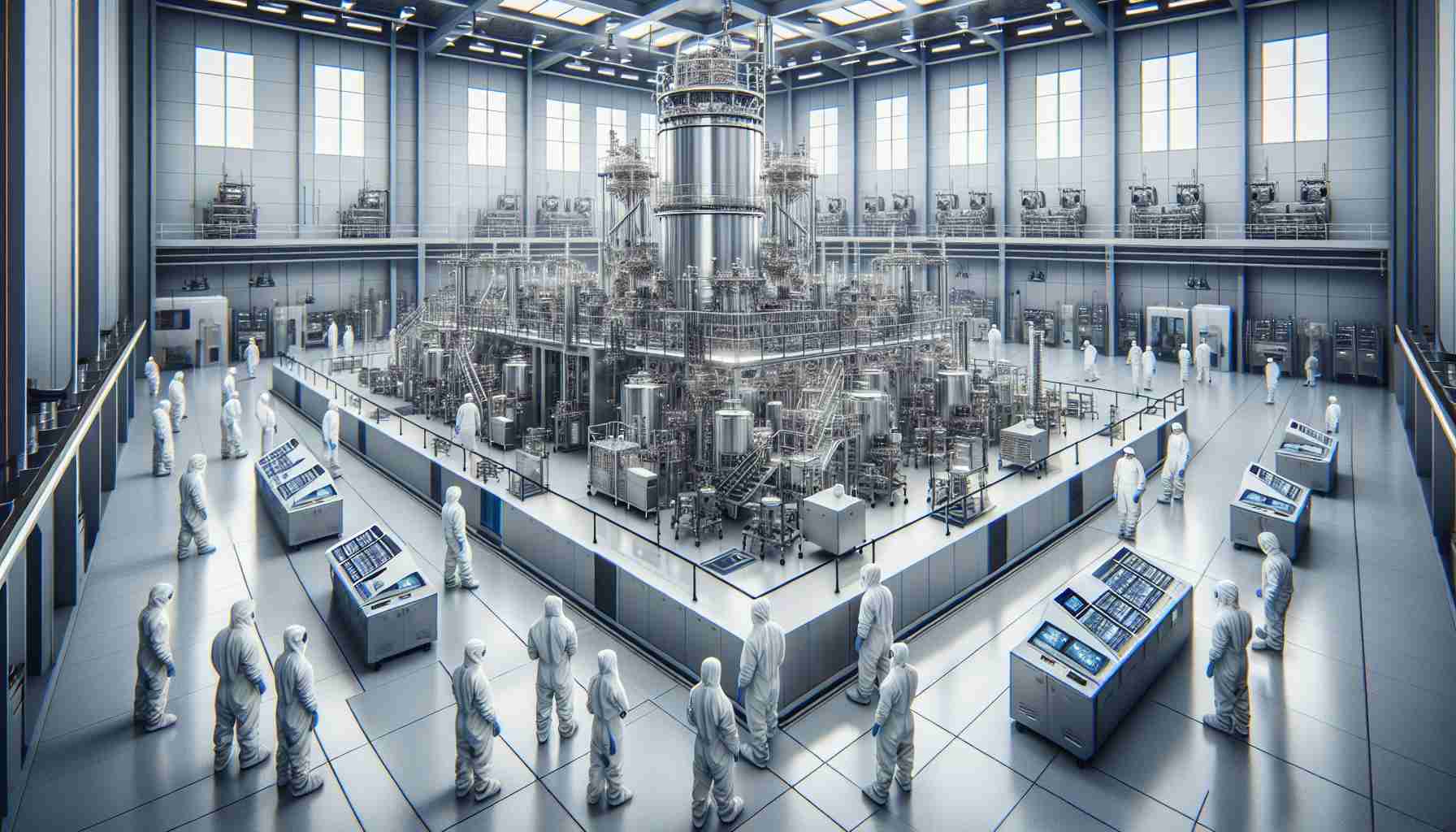

The cutting-edge institute is in the process of constructing not one, but two state-of-the-art bio-regenerative cleanrooms designed to redefine the standards for environmentally controlled spaces.

Sustainable Manufacturing is at the forefront of fostering breakthrough technologies and certifying sustainable practices for industrial production. Thus, the institute frequently evaluates cleanroom solutions to ensure they align with their commitment to eco-friendly manufacturing processes.

The essential role of these ultra-clean environments is to explore and refine the fundamental principles and practical applications essential in maintaining spotless and extremely arid conditions within manufacturing facilities of the future, as highlighted in a recent publication by CleanTech Solutions.

These innovative cleanrooms are designed to achieve an unparalleled pressure dew point of -40 degrees, setting a new benchmark in environmental control capabilities.

CleanTech Solutions, an industry leader hailing from the United States, has secured the prestigious contract to orchestrate the intricate development and execution of this ambitious initiative.

These ISO Class 1 certified cleanrooms represent the pinnacle of air purity standards, demanding a particle count of less than 2 particles exceeding 0.3 microns and an absolute absence of particles larger than 1.0 microns per cubic meter.

According to the information shared by CleanTech Solutions on their social media platforms, the completion and launch of these specialized cleanrooms are scheduled for the midst of 2024.

This pioneering project is poised to redefine the boundaries of sustainable manufacturing practices and revolutionize the landscape of cleanroom technology as we know it.

Additional facts related to the topic of revolutionizing cleanroom technology for sustainable manufacturing include:

– Cleanrooms are classified based on the number and size of particles permitted per volume of air. The classification ranges from ISO Class 1 (fewest particles) to ISO Class 9 (highest particle count).

– Cleanroom technology is essential across various industries, including pharmaceuticals, electronics manufacturing, biotechnology, and aerospace, to ensure product quality and safety.

– The design and construction of cleanrooms involve advanced HVAC systems, HEPA filters, air showers, and gowning protocols to maintain cleanliness and control contamination.

– Cleanroom operations require strict monitoring and control of temperature, humidity, and air pressure to meet industry standards and regulatory requirements.

– Investing in sustainable cleanroom technologies not only reduces environmental impact but also enhances operational efficiency and productivity.

Key questions related to the topic could include:

1. What are the cost implications of implementing sustainable cleanroom technologies compared to traditional cleanroom solutions?

2. How can advancements in cleanroom technology contribute to reducing energy consumption and waste generation in manufacturing processes?

3. What are the challenges associated with integrating sustainable cleanroom practices into existing manufacturing facilities?

The key challenges or controversies associated with revolutionizing cleanroom technology for sustainable manufacturing may include:

1. Balancing the initial investment cost of implementing advanced cleanroom technologies with long-term operational savings.

2. Ensuring regulatory compliance and certification for sustainable cleanroom practices to meet industry standards and demonstrate environmental responsibility.

3. Addressing potential resistance to change from industry stakeholders accustomed to traditional cleanroom methods.

Advantages of revolutionizing cleanroom technology for sustainable manufacturing include:

– Reduction in energy consumption and operating costs through efficient cleanroom design and HVAC systems.

– Enhanced product quality and safety by minimizing contamination risks and maintaining strict cleanliness standards.

– Improved environmental sustainability through lower carbon footprint and reduced waste generation.

Disadvantages of implementing sustainable cleanroom technologies may include:

– Higher upfront capital investment required for eco-friendly cleanroom construction and equipment.

– Limited availability of sustainable cleanroom solutions and expertise, leading to potential implementation challenges.

– Complex regulatory requirements and certification processes for sustainable cleanroom operations.

Suggested related links to the main domain on cleanroom technology and sustainable manufacturing:

– Sustainable Manufacturing Institute

– International Society for Pharmaceutical Engineering (ISPE)

– American National Standards Institute (ANSI)