Xiaomi, a major player in the technology sector, has strategically partnered with renowned battery manufacturers CATL and BYD to enhance the output of its electric vehicle, the SU7. This collaboration is set to increase the scale of production to meet the growing demand for EVs.

The improved manufacturing initiative comprises a two-shift system at Xiaomi’s factory, scheduled to take off in June, with an objective to amplify the monthly delivery to a milestone of over 10,000 units.

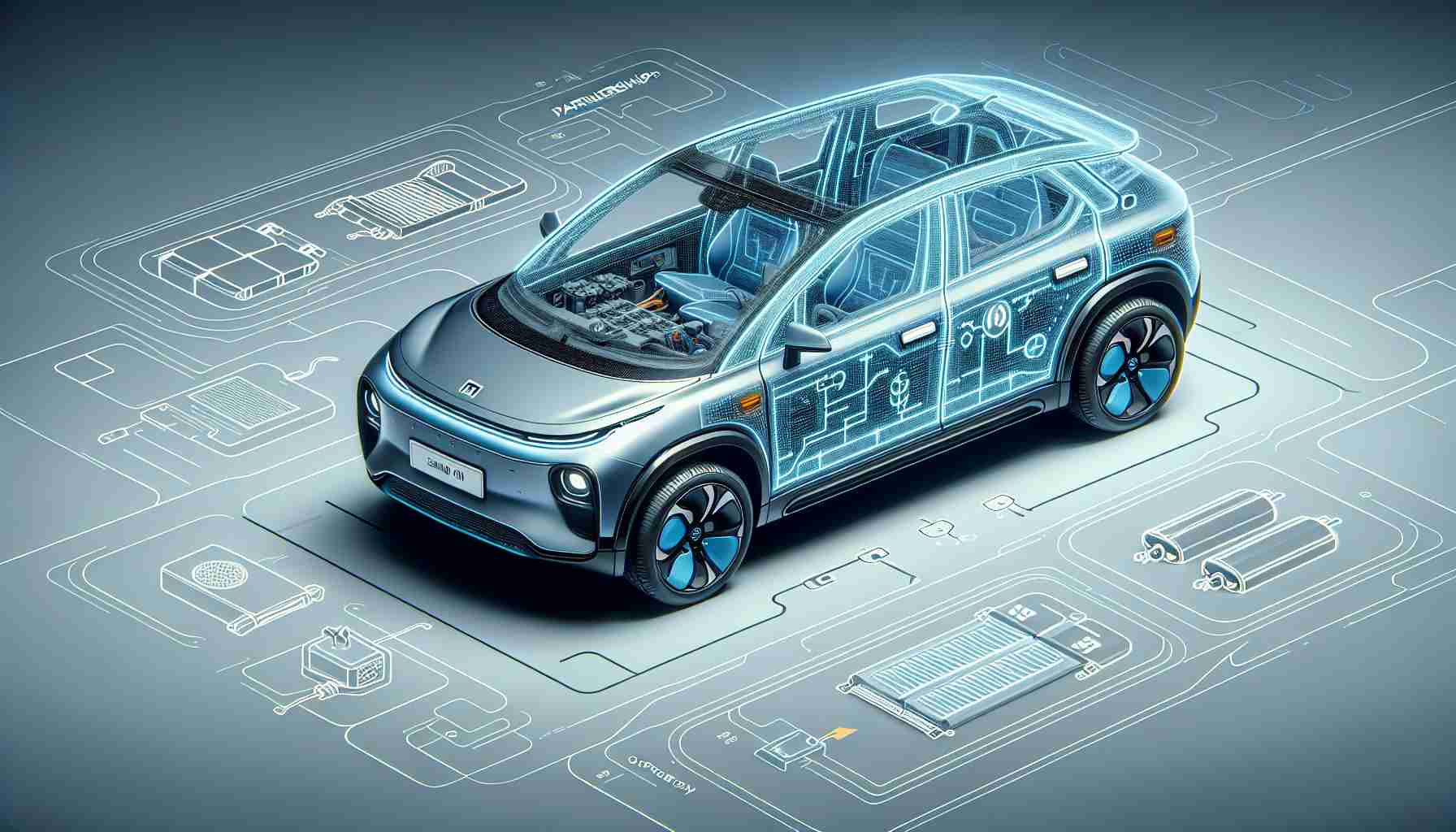

The SU7, which debuted in March 2024, quickly became a consumer favorite with its trio of offerings: the Standard, Pro, and Max models. A pivotal feature of both battery systems from CATL and BYD is their impressive CLTC range of 700 km, coupled with a rapid charging capability that restores 350 km of range in a mere 15 minutes.

The entry-level Standard model, initially equipped with BYD batteries, has now transitioned to harnessing CATL’s advanced battery technology. Meanwhile, the mid-tier Pro is powered by CATL’s Shenxing battery, and the flagship Max is energized by the potent Qilin battery from CATL. The different models each present varying battery capacities and travel ranges, ensuring that the SU7 caters to a wide array of customer preferences and needs.

Priced from 215,900 yuan (equivalent to 27,800 euros), the Xiaomi SU7 is poised to make a significant impact on the electric vehicle market, propelled by these strategic partnerships and enhanced production capabilities.

Key Questions:

1. What strategic advantages do the partnerships with CATL and BYD offer to Xiaomi?

These partnerships enable Xiaomi to leverage CATL and BYD’s expertise in battery technology and production, ensuring high-quality and reliable battery systems for the SU7. Through these collaborations, Xiaomi can also benefit from economies of scale, which could improve cost efficiency and potentially lower prices for consumers.

2. How does the increase in production capacity affect Xiaomi’s position in the EV market?

By ramping up production to exceed 10,000 units per month, Xiaomi is positioning itself to be a more significant competitor in the fast-growing EV market. An increase in production capacity can make the brand more capable of meeting demand and reducing delivery times, which is crucial in maintaining customer satisfaction and gaining market share.

3. What are the potential challenges that Xiaomi might face in this scaling-up effort?

Challenges include ensuring quality control at higher production volumes, the constant need for technological innovation to stay competitive, scalability of supply chain operations, and addressing the infrastructural requirements that come with rapid expansion.

4. What controversies or concerns may arise from the partnerships and production ramp-up?

Concerns could include dependency on battery suppliers, the impact of such a partnership on other EV manufacturers and suppliers, and potential environmental impacts of the increased production pace.

Advantages:

– Access to high-performance battery technology.

– Capacity to meet the growing market demand for EVs.

– Potential cost savings due to economies of scale.

– Rapid charging capabilities attracting consumers looking for convenience.

Disadvantages:

– Potential challenges in maintaining product quality at higher production volumes.

– Risk of supply chain disruption.

– Heavy reliance on partners for critical components such as batteries.

– Environmental impact of ramping up production which could include increased consumption of resources and higher emissions.

Regarding related links, for a glimpse at the broader business and technological context you can visit the official websites of Xiaomi, CATL, and BYD. Each site may provide additional insight into the companies’ philosophies, other products, and news about their collaborations. Make sure to verify the links for their authenticity and relevance to your research.