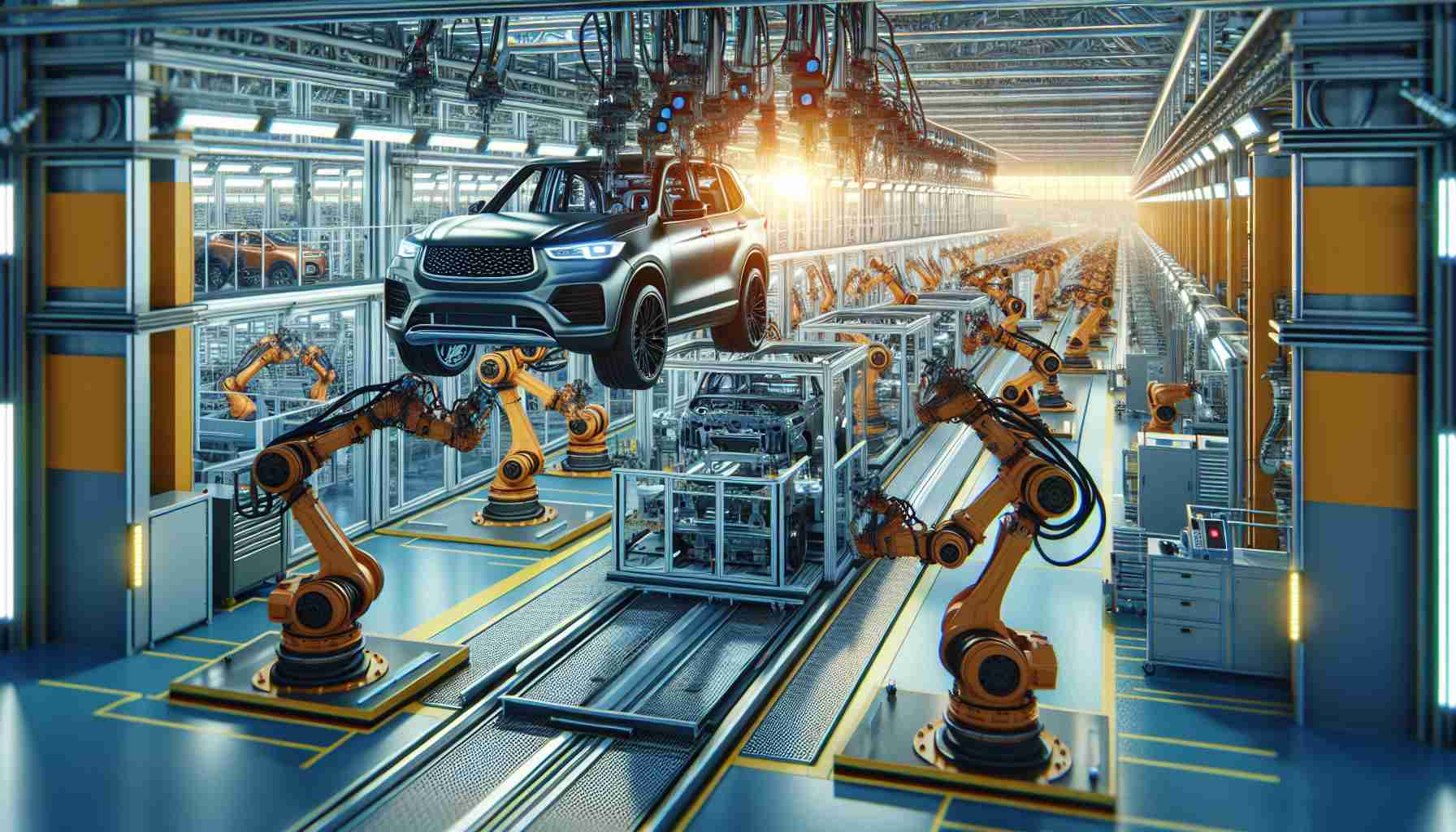

Utilizing cutting-edge automation technology, Xiaomi’s revolutionary electric vehicle (EV) factory has set a new benchmark in the automotive manufacturing industry. In this facility, the process for creating an electric SUV is so efficient that a complete vehicle rolls off the assembly line every 76 seconds. This impressive feat showcases the company’s commitment to innovation and efficiency in the EV space.

Despite Xiaomi’s manufacturing prowess and the popularity of the SUV, it has been reported that the tech giant is incurring substantial losses with each EV produced. Sources indicate that the cost overrun per vehicle surpasses $9,000, hinting at the significant financial challenges Xiaomi faces as it navigates the competitive electric car market.

As the company continues to refine its production processes, industry observers are closely watching to see how Xiaomi will address these financial hurdles. The ability to rapidly manufacture vehicles is undoubtedly an advantage, but balancing speed with sustainable economics will be critical for Xiaomi’s long-term success in the electric vehicle industry.

Automation in EV Manufacturing

Automation in electric vehicle manufacturing is crucial for increasing production rates and decreasing costs over time. Companies like Tesla have set precedent in using automation to manufacture EVs, although they have faced challenges with over-automation in the past. Implementing advanced robotics and smart manufacturing systems, like those in Xiaomi’s EV plant, allows for a more streamlined production process that can lead to higher consistency in quality and reduction in human error.

Cost Overruns

The reported $9,000 cost overrun per EV reflects the complex financial landscape of entering the EV market. For startup automakers or tech companies pivoting to vehicle production, initial costs can be steep due to investments in new technologies, research and development, and establishing a supply chain. This can lead to temporary financial losses which companies aim to overcome as they scale up production and sales volume.

Key Challenges

One of the crucial challenges in the EV industry is achieving profitability while investing in cutting-edge technologies, something Xiaomi seems to be currently grappling with. Battery cost and technology, supply chain management, and competition with established automotive giants are ongoing concerns. Additionally, becoming competitive often requires significant capital investment.

Controversies

There are controversies and debates around the degree of automation that is sustainable and effective. Over-reliance on automation can lead to pitfalls, as seen with Tesla’s “production hell” a few years ago, where over-automation slowed down production rather than speeding it up. Finding the right balance between automated and human elements is key.

Advantages

The advantages of advanced automation include:

– Increased Production Speed: A car every 76 seconds is a testament to high efficiency.

– Consistency and Quality: Automated systems can perform certain tasks with greater precision than humans.

– Operational Cost Reduction: In the long term, automation can reduce labor costs and wastage.

Disadvantages

On the other hand, disadvantages may include:

– High Initial Investment: The initial cost of installing automation technology can be prohibitive.

– Job Displacement: Increased automation can lead to reduced need for labor, affecting employment.

– Flexibility Concerns: Automated systems may lack the flexibility of human workers, which can be problematic when dealing with production issues or transitioning to new models.

For those interested in related information, you may want to visit the official websites of Xiaomi or similar entities in the EV and automation spaces, using the following format:

Xiaomi Official

The source of the article is from the blog guambia.com.uy