In the realm of cycling, the aesthetic allure and functional sophistication of bicycle components have long fascinated enthusiasts. Recalling a time when the market saw a surge of startups crafting splendid derailleurs, the narrative now shifts to a modern contender emerging to challenge the dominance of industry giants. Vivo Cycling has stepped into the spotlight with a bespoke offering that promises to elevate the cycling experience.

Earlier this year, the brand caught the attention of the bike world with their high-end, personalized shifter, allowing cyclists to fine-tune elements from the paddle shape down to the cable tension adjuster. Now, they’re introducing a derailleur that not only complements its shifter counterpart but also captures gazes with its striking design.

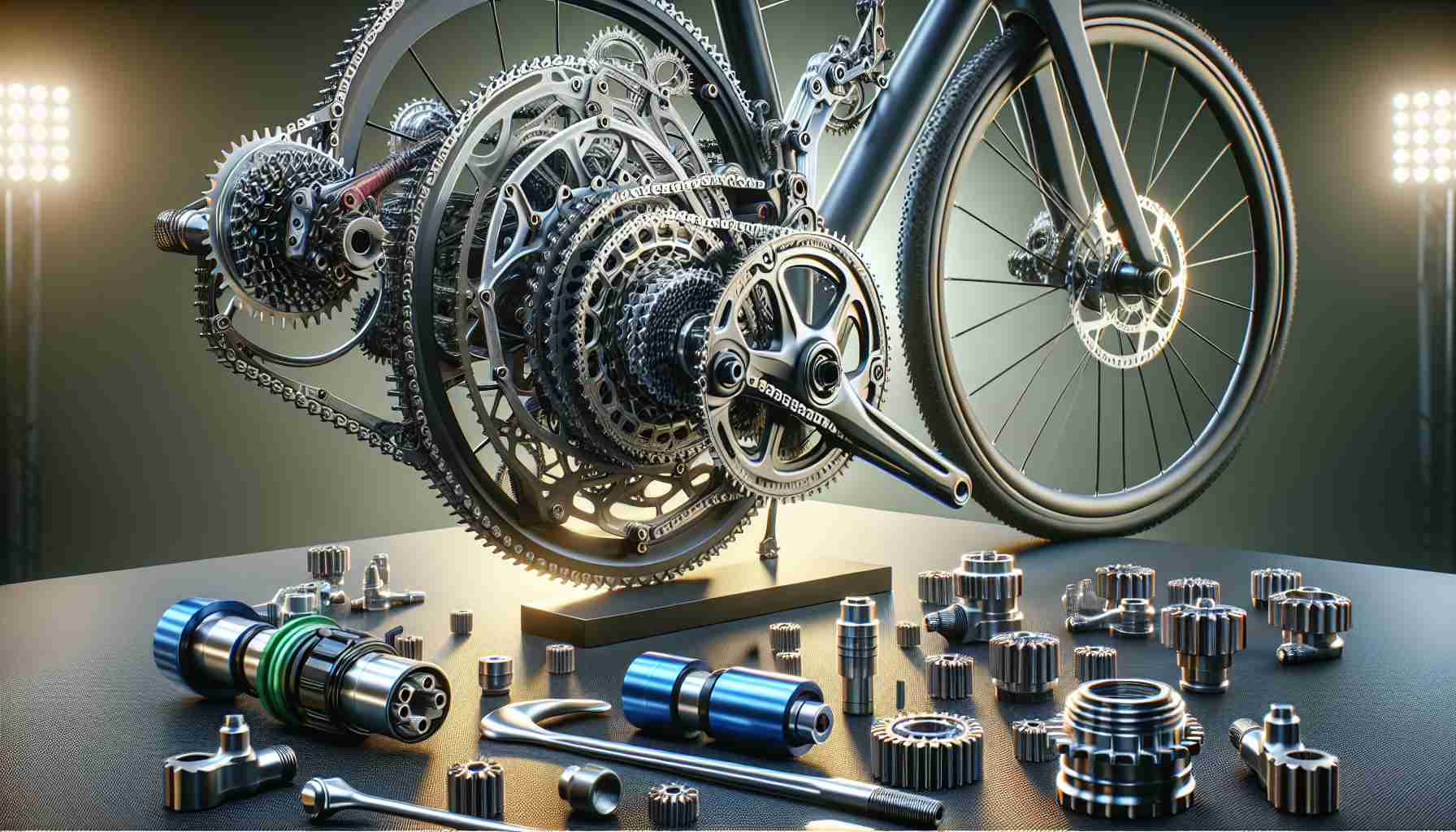

The brain behind this leap forward in cycling gear is John Calendrille, a veteran in drivetrain development, whose latest project is driven by robust materials and meticulous craftsmanship. Vivo’s upcoming derailleur boasts an all-metal construction with 7075 aluminum at its core, eliminating plastic from its anatomy, and ensuring a sturdy and lightweight build.

Addressing the needs of modern cyclists, this derailleur is engineered for precision, accommodating 12-speed cassettes with cog sizes expanding to an impressive 52 teeth. With its eight cartridge bearings spread across the pivots and another sealed one at the cable pulley, coupled with resilient titanium hardware, the device aims to redefine smooth and reliable shifting.

The initial iteration, featuring nylon pulley wheels, tips the scales at a modest 315 grams, challenging Shimano’s lighter XTR variant. Notably, Vivo’s derailleur is not only compatible with their custom shifter but also expected to mesh well with SRAM’s, opening up possibilities for gear customization.

Dedicated to enduring performance, Vivo has designed their derailleur to be entirely rebuildable, featuring an adjustable friction clutch. As the cycling community eagerly awaits its release set for later in the year, the anticipated price point hovers between $315 and $375, positioning it as a premium option for those who demand nothing less than the best.

Key Questions & Answers:

1. What sets Vivo Cycling’s drivetrain components apart from others on the market?

Vivo Cycling’s components are customizable, built with high-end materials such as 7075 aluminum, and designed to accommodate modern 12-speed cassettes with large cog sizes. They focus on an all-metal construction, eliminating plastic for durability. The company offers a derailleur that is entirely rebuildable and features an adjustable friction clutch, catering to those seeking a premium, durable, and personalized cycling experience.

2. How does the introduction of Vivo Cycling’s products affect the cycling industry?

Vivo Cycling’s products represent a step forward in terms of customization and material excellence in drivetrain components. This could potentially challenge existing major players in the market by setting higher standards for the quality and adaptability of components and could also inspire further innovation and competition within the industry.

3. What are the potential challenges and controversies associated with customizable drivetrain components?

Challenges could include maintaining compatibility with different cycling systems, ensuring the durability of customizable parts, and meeting the varied needs of cyclists without compromising performance. Controversies could arise regarding the cost of premium components, barriers to entry for novice cyclists due to the technicality of customization, and the potential environmental impact of producing high-end, niche products.

Advantages and Disadvantages:

Advantages:

– Customization: Allows cyclists to tailor components to their specific preferences and needs.

– Material Quality: The use of robust materials such as 7075 aluminum and titanium ensures strength and lightweight properties.

– Rebuildable Design: Contributes to sustainability, as parts can be replaced or repaired rather than the whole unit being discarded.

– Precision Engineering: Offers smoother and more reliable shifting performance for a better riding experience.

Disadvantages:

– Cost: Premium materials and the option to customize can make these components expensive, potentially limiting their market to enthusiast or professional cyclists.

– Complexity: Customization options might be too complex or daunting for less experienced cyclists.

– Compatibility: While designed to be compatible with other brands, there may still be issues when mixing components from different manufacturers.

I can recommend a few related links that might have further information on the cycling industry and innovations, assuming their domains have not changed recently:

– Shimano – a major player in cycling components.

– SRAM – another leading manufacturer in the bike industry.

– BikeRadar – a source for bike reviews, gear news, and cycling advice.

Please note that these are suggestions, and I advise verifying the URLs before considering them as 100% valid due to the fast-paced nature of changes on the internet.

The source of the article is from the blog maestropasta.cz