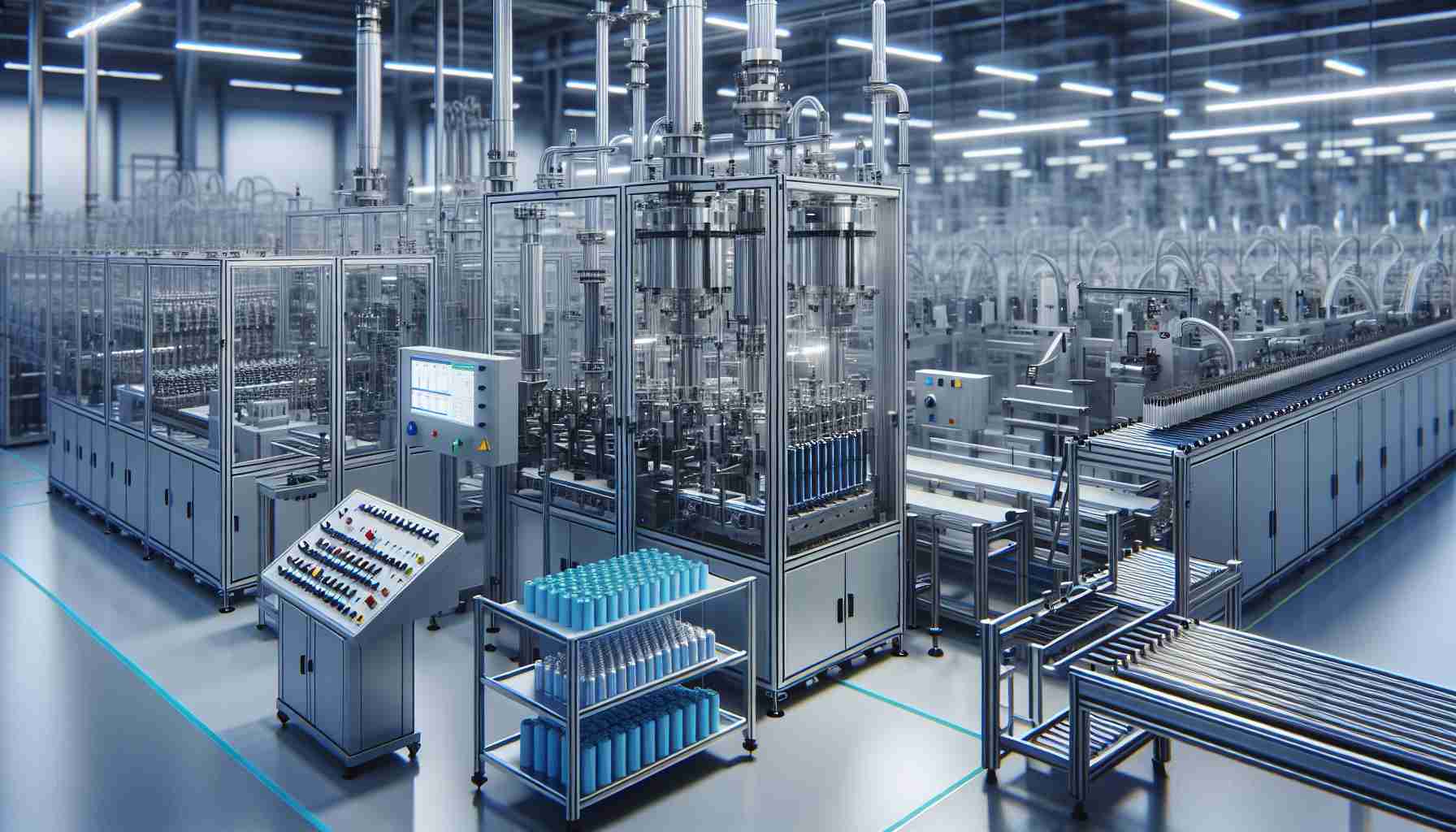

FREYR Battery has achieved a significant milestone in the automation of battery cell production by successfully conducting trials of automated casting of active electrolyte at its Customer Qualification Plant (CQP) in Mo i Rana, Norway. This marks an important step forward in the company’s efforts to automate battery cell production, with the expectation of commencing production of functional battery cells for customer samples in the first half of 2024. This is one of FREYR Battery’s priority initiatives.

The company also announced that its year-end cash and cash equivalents balance in 2023 amounted to $275.7 million, exceeding the previously forecasted $250 million. Additionally, the company is preparing part two of its Title 17 application to the U.S. Department of Energy Loan Programs Office in the first quarter of 2024, aiming to strengthen its position in the battery value chain in the United States.

The introduction of active electrolyte and initiation of dry room operations are key milestones preceding the completion of commissioning packages for casting and cell assembly units. Mike Brose, Manager of the Asset Mo Team at FREYR Battery, expressed satisfaction with the completion of pre-commissioning key performance indicators and the start of full-scale automated production. The 24M SemiSolid technology simplifies the production process by incorporating electrolyte at the beginning, eliminating the need for solvent recovery. FREYR Battery has nearly completed the delivery of production line equipment and test packages at the CQP, with the next steps involving anode casting trials and the integration of cast grids using Multi-Carrier Systems (MCS). CEO Birger Steen emphasized the technical complexity and progress in implementing the SemiSolid technology on an industrial scale for the production of B-grade cell prototypes for customer evaluation.

FREYR Battery anticipates potential revenues of $9 to $10 billion from conditional offtake agreements and long-term sales agreement with a total capacity of approximately 130 GWh. The automation of the production line at CQP is crucial for converting these agreements into binding commitments in line with the goals of the inflation reduction act.

FAQ section based on the main topics and information presented in the article:

1. What is the significance of the trial of automated casting of active electrolyte for FREYR Battery?

The trial of automated casting of active electrolyte is an important step forward in the company’s efforts to automate battery cell production. The company expects to commence production of functional battery cells for customer samples in the first half of 2024.

2. What is the current financial position and development plans of FREYR Battery?

The company’s year-end cash and cash equivalents balance in 2023 amounted to $275.7 million, exceeding the previously forecasted $250 million. The company is preparing part two of its Title 17 application to the U.S. Department of Energy Loan Programs Office to strengthen its position in the battery value chain in the United States.

3. What are the key milestones in the automation of battery cell production by FREYR Battery?

The introduction of active electrolyte and initiation of dry room operations are key milestones preceding the completion of commissioning packages for casting and cell assembly units. The 24M SemiSolid technology developed by FREYR Battery simplifies the production process by incorporating electrolyte at the beginning, eliminating the need for solvent recovery.

4. What are the anticipated revenues of FREYR Battery and what are their basis?

FREYR Battery anticipates potential revenues of $9 to $10 billion from conditional offtake agreements and long-term sales agreement with a total capacity of approximately 130 GWh. The automation of the production line at CQP is crucial for converting these agreements into binding commitments in line with the goals of the inflation reduction act.

Definitions of terms and jargon used in the article:

– Battery cells: Electrochemical devices that store and release energy in the form of electricity through chemical reactions.

– Active electrolyte: A substance that conducts electric current in a battery cell and enables electrochemical reactions.

– Production automation: The introduction of automatic processes and systems to increase production efficiency and quality.

– CQP (Customer Qualification Plant): FREYR Battery’s facility where battery cell testing and initial production take place.

– Title 17: Part of U.S. law concerning energy financing programs, including battery technologies.

– U.S. Department of Energy Loan Programs Office: The office of the U.S. Department of Energy responsible for energy loan programs.

Suggested related links:

FREYR Battery homepage

Source: “FREYR Battery achieves a significant milestone in automated production of battery cells” article on the FREYR Battery website.

The source of the article is from the blog oinegro.com.br