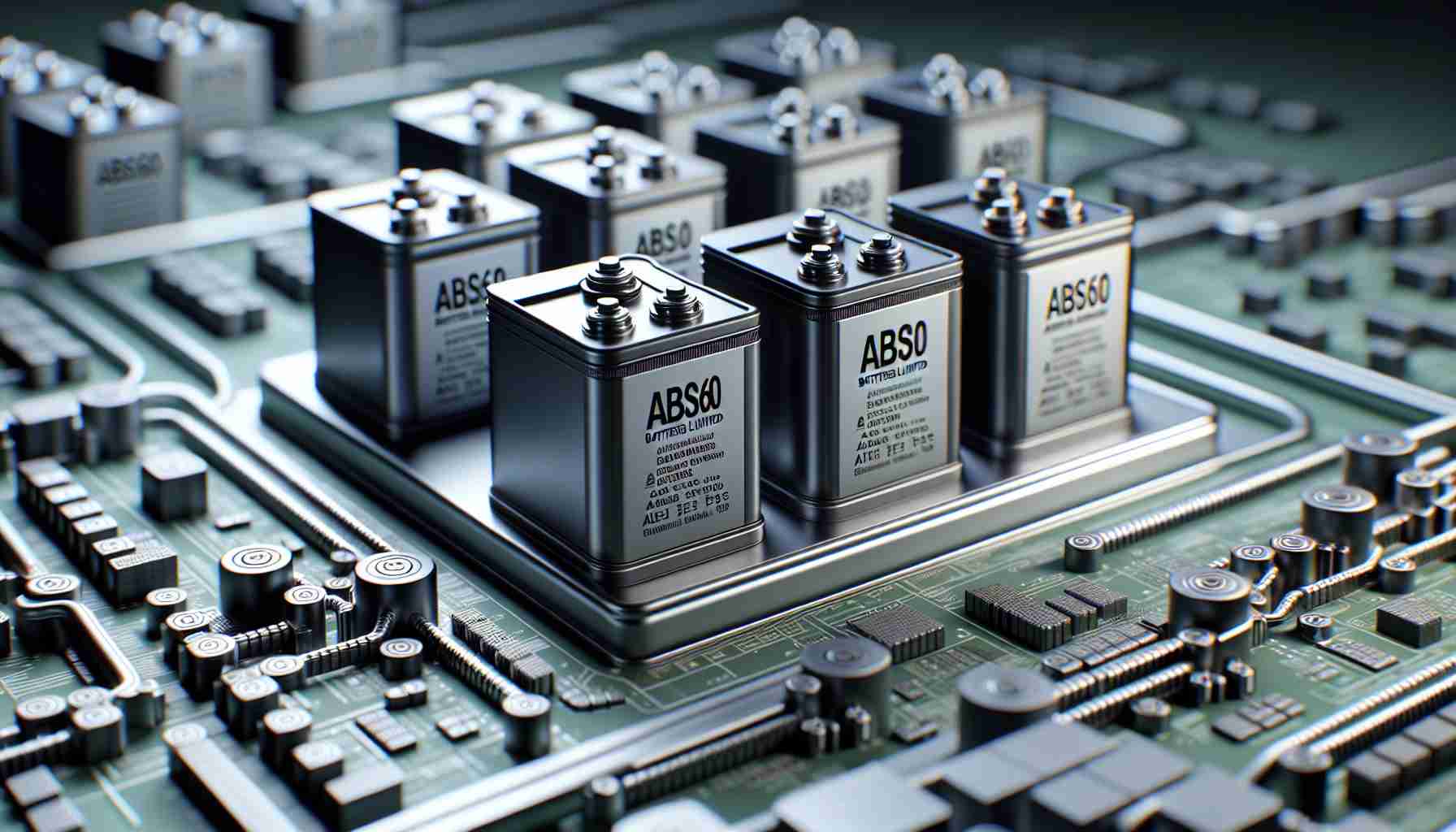

Altech Batteries Limited (ASX:ATC) (FRA:A3Y) (OTCMKTS:ALTHF) has recently shared an update on the progress of its ABS60 60 kWh CERENERGY(R) battery prototypes. These batteries, designed specifically for the grid storage market, have undergone significant upgrades and are now being manufactured for performance testing and customer use.

Previously, Altech’s joint venture partner, Fraunhofer IKTS, had developed battery packs with capacities of 5 kWh and 10 kWh. However, with the establishment of the joint venture with Altech, a substantial upgrade was undertaken, resulting in the development of a 60 kWh battery pack.

The manufacturing process of these battery prototypes has been carried out at Fraunhofer IKTS’ pilot line in Germany. The line has undergone a comprehensive redesign to accommodate the production of the 60 kWh prototypes. Specialized tools and machinery have been developed and implemented for the production of the required battery cells.

Each ABS60 battery pack consists of 240 CERENERGY(R) cells, rated at 2.5 V, organized in 4 rows and stacked 5 modules high. These substantial battery packs have specific dimensional specifications of 2.6 meters in height, 0.4 meters in length, and 1.0 meter in width. With their Ingress Protection (IP) 65 standard, the battery packs are designed to be dust and weatherproof, ensuring high levels of sealing effectiveness.

The manufacturing process involves several crucial stages, including blending ceramic components, high-pressure pressing, tube formation, and sintering at high temperatures. Fraunhofer IKTS’ pilot plant facility successfully completed the ceramic tube production, and half of the required tubes have been manufactured. The battery cathode electrolyte, made from sodium chloride and nickel powder granules, was also produced.

Currently, the process of cell assembly is ongoing, including vacuum filling, heating, and welding operations. In order to ensure precise alignment and verify the components, thorough examinations are conducted using an industrial micro computed tomography (uCT) scanning system. These tests have shown satisfactory results so far.

Once the cells are finalized, they will be integrated into a module frame and connected using the Cell Contacting System (CCS) designed by Hofer AG. Konig Metall GmbH has provided the casings for the battery housing, and testing racks for charge and discharge cycling will be furnished by Fraunhofer IKTS.

Once completed, the prototypes will be made available to select potential customers for collaboration and to showcase the practical applications and benefits of the ABS60 series. Altech Batteries Limited remains committed to advancing battery technology for the grid storage market, and this update marks a significant step forward in that direction.

The source of the article is from the blog crasel.tk