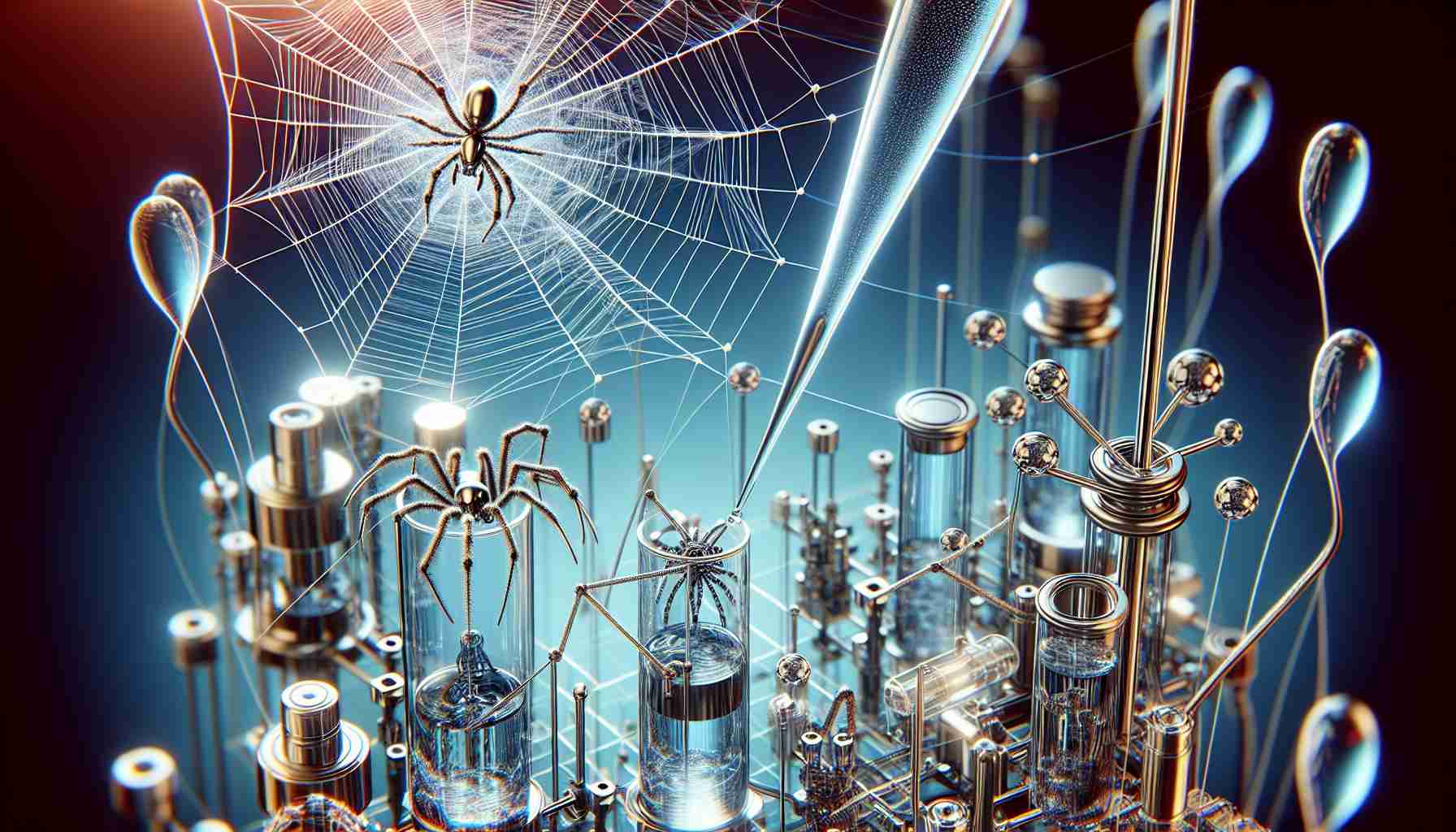

Scientists from the RIKEN Center for Sustainable Resource Science in Japan have developed a device for producing artificial spider silk that perfectly imitates the natural silk produced by spiders. Large-scale extraction of spider silk has proven impractical for several reasons, but now scientists are working on creating a mechanism to produce it in the laboratory.

Spider silk is a biopolymer fiber made of proteins called spidroins, which have highly repetitive sequences. Silk fibers contain beta sheets that need to be properly arranged in order to have unique mechanical properties. The RIKEN scientists decided to mimic this process using biomimicry. They utilized microfluidics, which involves the flow and manipulation of small amounts of fluid in narrow channels, to create spider silk. In this method, a solution of spidroin precursors was placed at one end of a rectangular container containing channels, and then it was drawn towards the other end using a vacuum. During the flow, spidroins were exposed to precise changes in the chemical and physical environment. Under the right conditions, the proteins began to fold and form silk fibers with a specific and complex structure.

The researchers discovered that using force to push the proteins did not work; only the use of a vacuum to draw the spidroin solution allowed for the assembly of continuous silk fibers with the proper arrangement of beta sheets.

“The microfluidic system proved surprisingly robust after stabilizing and optimizing various conditions,” said Ali Malay, a scientist from RIKEN. “The fiber assembly was spontaneous, extremely fast, and highly repeatable. Importantly, the fibers possessed the characteristic hierarchical structure found in natural spider silk.”

According to the research authors, in order to obtain fibers, there must be a minimum shearing stress of about 72 Pa, and the formation of beta sheets depends on the presence of polyalanine blocks in the sequence. The resulting MaSp2 fiber had a beta sheet content (29.2%) comparable to natural spider silk.

The ability to artificially produce silk using this method can not only help reduce the negative impact of the current textile industry on the environment but also the biodegradable and biocompatible nature of spider silk makes it ideal for biomedical applications such as sutures and artificial ligaments.

“To achieve real impact, we need to scale up our fiber production method and make it a continuous process. We will also evaluate the quality of our artificial silk based on several metrics and make further improvements based on that,” said Keiji Numata, a professor of biomaterials chemistry at the University of Kyoto.

The findings of the RIKEN scientists are promising and can bring many benefits to the natural environment and medicine. Artificial spider silk may prove to be an alternative source of durable and eco-friendly materials.

FAQ Section:

1. What is spider silk?

Spider silk is a biopolymer fiber made of proteins called spidroins. It is a fiber with a highly repetitive structure.

2. Why are scientists trying to produce artificial spider silk?

Large-scale extraction of spider silk has proven impractical, so scientists are working on creating a mechanism to produce it in the laboratory.

3. How do scientists produce artificial spider silk?

Scientists utilize biomimicry, which involves mimicking processes found in nature. Using microfluidics, they manipulate small amounts of fluid in narrow channels to create spider silk.

4. What are the applications of artificial spider silk?

Artificial spider silk can be used in the textile industry, biomedicine (e.g. sutures, artificial ligaments), and other fields where durable and biocompatible materials are required.

Definitions:

– Spider silk: A biopolymer fiber made of proteins called spidroins, which have highly repetitive sequences and unique mechanical properties.

– Microfluidics: A field of science that deals with the flow and manipulation of small amounts of fluids at the microscale, often in narrow channels.

– Beta sheets: Arranged blocks in the structure of spider silk that give it specific mechanical properties.

Links:

– RIKEN

– University of Kyoto

The source of the article is from the blog kunsthuisoaleer.nl