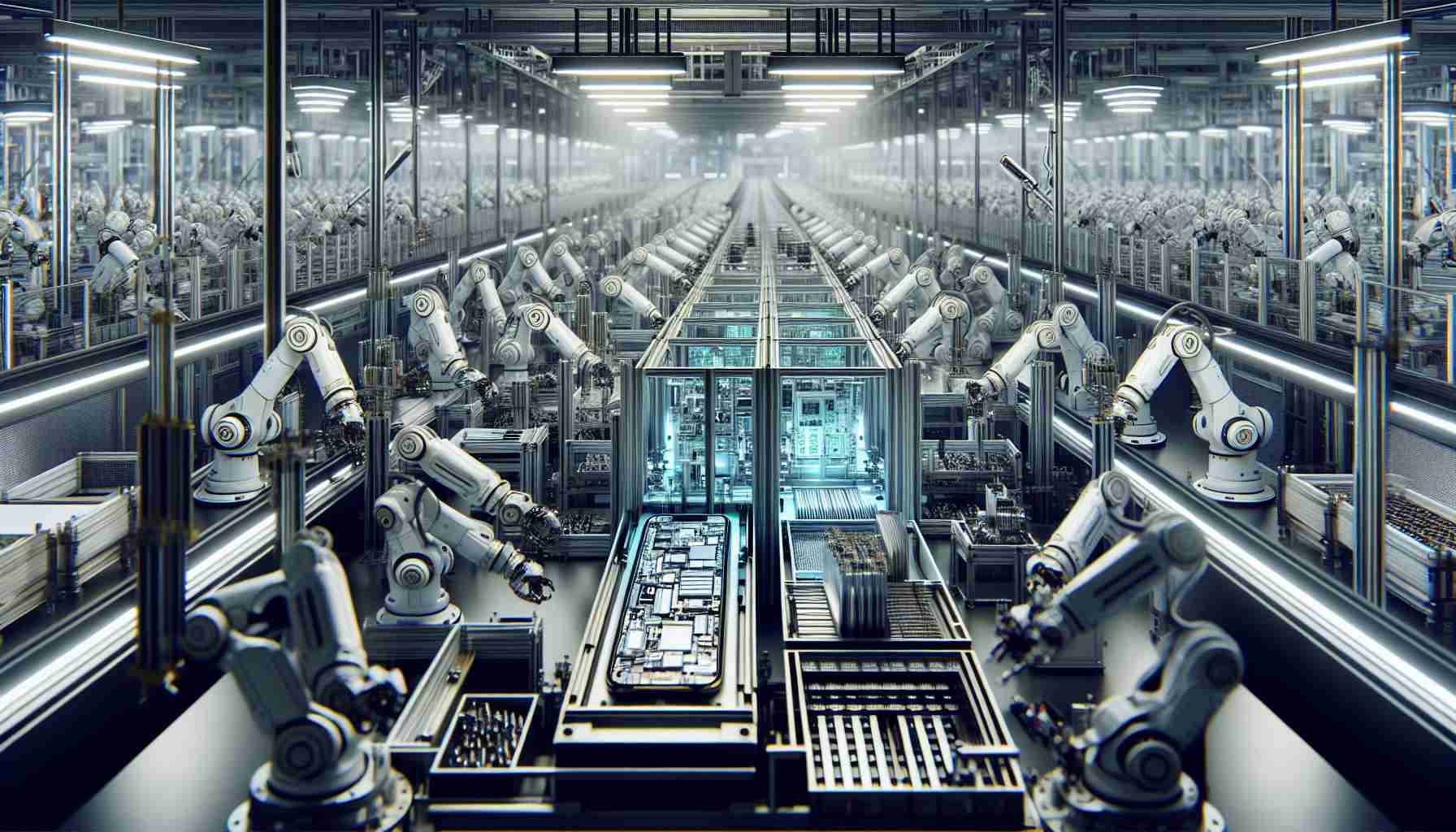

Xiaomi has unveiled a groundbreaking automated smartphone production facility that operates without human intervention, making quite an impression on the public. The new plant, located in Changping, Beijing, spans an impressive 81,000 square meters and comes with a hefty price tag of $330 million.

Projected to manufacture 10 million high-end smartphones annually, the factory will not only produce existing models but will also handle the upcoming foldable phone releases like the MIX Fold4 and Mix Flip set to debut in July.

CEO Lei Jun showcased the incredible automated system in a video shared on social media. The plant’s Hyper IMP, described as Xiaomi’s intelligent production platform, acts as the brain of operations, proactively solving challenges and enhancing manufacturing efficiency.

The fully automated system incorporates 11 production lines, with all primary processes being automated. Xiaomi has developed specialized manufacturing software to achieve this remarkable feat, ensuring seamless operation.

Employing intricate machinery working collaboratively, the factory excels at its tasks. Even micron-sized dust collectors are utilized to maintain a pristine environment. Smart machines also play a pivotal role in quality control, with the capacity theoretically to produce a smartphone every second.

As per reports, the plant is expected to commence operations soon. Since early 2019, Xiaomi has progressively integrated automation technologies into its production processes. Smart factories in Yizhuang, Beijing, have been operational and ready for production, marking a significant milestone for the company’s swift success in this new sector.

Xiaomi’s Revolutionary Robotic Factory Redefining Smartphone Production Dynamics

Xiaomi’s innovative push in the realm of smartphone manufacturing continues with the unveiling of a pioneering robotic factory poised to revolutionize production processes. Beyond the impressive scope and scale detailed in the initial announcement, there are additional intriguing facets to consider.

Unveiling Cutting-Edge Technology

The new facility represents a significant leap forward in manufacturing prowess, with the integration of advanced robotics and artificial intelligence. Notably, the factory boasts a sophisticated self-learning system that continually refines operations based on real-time data analysis.

Setting New Industry Standards

One essential question arising from this development is how Xiaomi’s foray into automated production will influence industry norms. By showcasing the potential for heightened efficiency and quality control, the company is likely to prompt competitors to reevaluate their own manufacturing strategies.

Addressing Challenges and Controversies

Key challenges facing Xiaomi in this venture include ensuring the seamless integration of automation while safeguarding against potential technical glitches or system failures. Controversies might arise concerning the displacement of human workers by machines, highlighting the importance of ethical considerations in transitioning to fully automated production.

Advantages and Disadvantages

The advantages of Xiaomi’s robotic factory are evident in its ability to boost production capacity, enhance product quality, and streamline operations for increased output. However, potential disadvantages could encompass initial high costs of implementation, ongoing maintenance expenses, and societal concerns regarding the impact on human employment.

In conclusion, Xiaomi’s embrace of automated manufacturing signifies a bold step towards technological innovation and operational excellence within the smartphone industry. By continually pushing boundaries and refining processes, the company is poised to set new benchmarks for efficiency and quality in production.

For further insights on Xiaomi’s technological advancements and strategic developments, visit www.xiaomi.com.